Bottle and Jar Labeling Machine with Longer Wrap and Tilt Adjustments

Round Bottle and Round Jar Labeling Machine with Long Wrap and Tilt Adjustments

Taking our standard LabelOn Basic 500-WRAP, this machine had the following options added for our client:

Basic 500-WRAP, this machine had the following options added for our client:

1) Long Wrap Conveyor;

The Standard Wrap Labeling Conveyor is 300 mm Long (11 7/8″)

The Long Wrap Labeling Conveyor is 400 mm Long (15 3/4″)

This Option includes a Main Conveyor width Upgrade to 152.4 mm (6″).

This client was advised to use a Vacuum Wrap Conveyor for this Job, however, label end alignment was not so critical for their client.

With the above, the Digital fine tuning of Synchronized Speed Controls on the touch panel coupled with Fine Tilt Controls on the label head achieved excellent label ends alignment with their extra-long label.

2) Tilt Adjustments – Tapered Products;

There is a significant amount of solidly engineered hardware included with this option. The Label Head Mounting is upgraded from the Standard Wind-Up/Down mounting (A Z-Axis Adjustment) to Mounting that has 3 Axis of Directional Adjustment (X-Y-Z) and Two Axis of Tilt Adjustment (X-Y).

2.1 Fine Controls of Label Head Positioning.

The added Adjustments can extend the alignment capabilities of the front and back ends of the labels beyond the recommended 85% for this method of label application.

With quality containers, precision height matching of the leading and trailing edge of long labels up to 95% wrap are possible with this machine – even 100% wrap labels.

2.2 Tapered labeling (Requires Tilt Adjustment Options)

This client sometimes has containers that have a slight taper. Such Containers tend to rise in the WRAP CONVEYOR section.

To counter this rising container, the WRAP Conveyor Mounting has its mounting upgraded to include a Y-Axis Tilt Adjustment.

Also, the Backing Plate has its Mounting Upgraded to have a Y-Axis Tilt Adjustment.

Understanding Tapered Round Container Labeling

A spinning rotating tapered product has a surface speed that varies with the height of the product. That is because the circumference of the container is different at different heights. A well Designed Label for a Tapered Round Container will have a “Smile Shape”.

The WRAP CONVEYOR Labeling method is ONLY recommended for very slightly tapered products. If you look at smile labels as they sit on the label roll the top edge and the bottom edge of the label that will peel off will move relative to the top edge and bottom edge of the label roll (that remains on the machine). When we dispense/peel a label from the roll, on the machine, the label roll does not move up or down it remains at the same level.

HOWEVER, the top edge and the bottom edge of the smile shaped label does move up and down as the label is dispensed. With the standard or long WRAP CONVEYOR Labeling method, for the duration of the label dispensing, the label is in contact with the spinning container.

Labels on the Dispensing Label Head DO NOT want to go up and down.

Labels on the Spinning Container DO want to go up and down to conform/wrap onto the spinning container and stay at the same height on the container.

For containers that have more than a slight taper, this “tug of war” can lead to label tracking issues on the Label Dispensing Head and on the Container itself.

Vacuum Wrap Option Available:

Vacuum Wrap Labeling Machine – LabelOn Basic – VW

A Vacuum Wrap enables the label(s) to be completely released from the backing paper prior to application. Hence, labels are free to “slide” on the Vacuum Belt in a path that matches the spinning surface of the product. This eliminates the “tug of war” between the label dispensing head and the Container’s Spinning surface and removes the tracking issues on the Label while reducing tracking issues on the Container as the label wraps/conforms to the container.

At LabelOn we have listened to the market very carefully.

we have listened to the market very carefully.

Economic Labeling Machines need to operate like the more expensive and larger labeling machines. The LabelOn Basic Labeling machines need to get out a good level of production volume, accurately and (*importantly*) with the ease of set up found on our bigger budget labeling machines.

Basic Labeling machines need to get out a good level of production volume, accurately and (*importantly*) with the ease of set up found on our bigger budget labeling machines.

Our Basic Labeling Machines have Touch panel controls and Synchronized Motor Speeds. When you have Basic Labeling Machines with the features we have packed into our Basic Series Bottle Labeling Machines you have Labeling Machines that require a much lower operator skill set than the skill set required to operate other low cost Labeling Machines that fail to include the features of the LabelOn Basic Range of Low Cost high Production Labeling Machines.

Basic Range of Low Cost high Production Labeling Machines.

Password Protected Access

A relatively New standard feature on our Basic Series is Password protected access to the machine controls. This gives you the option to have only authorized staff make changes to the machine’s touch screen settings.

www.Label-On.com

Instant Chat Link: https://view.label-on.com/chat

Contact details:

(North America) www.adeneli.com

(Asia Pacific) www.benefel.com.au

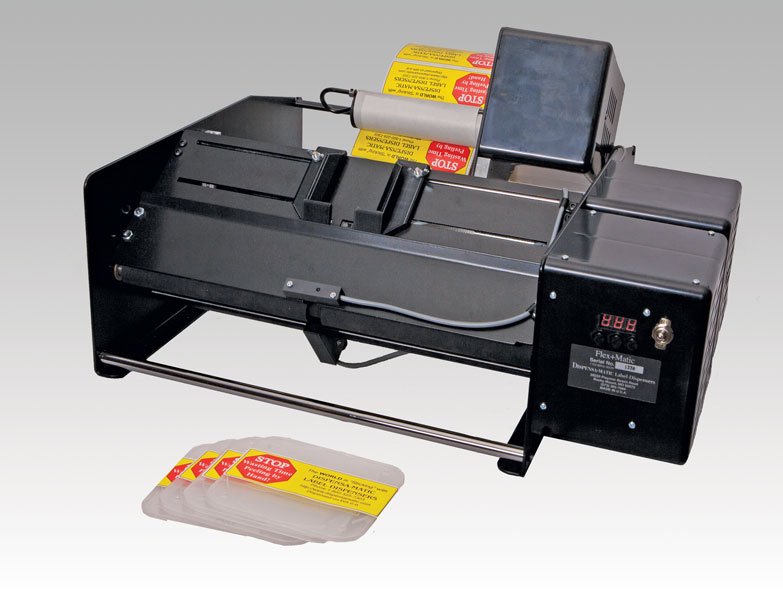

Flat Bags Sheets Case Labeling

Flat Bags Sheets Case Labeling helping you take the step from hand applying to machine applied labels. This Flat Label Applicator Machine – Made in the US solves the problem of labeling Flat Bags, Flat Sheets, Flat Case with a benchtop labeling machine.

helping you take the step from hand applying to machine applied labels. This Flat Label Applicator Machine – Made in the US solves the problem of labeling Flat Bags, Flat Sheets, Flat Case with a benchtop labeling machine.