Rebar (short for reinforcing bar) is a steel bar or mesh of steel wires used as a tension device in reinforced concrete and reinforced masonry structures to strengthen and hold the concrete in tension.

Rebar fabricators supply various grades, sizes and shapes to meet the requirements of construction projects. Given all the types of rebar, construction sites need a means to quickly identify the correct bundle for each part of a project. Color is the easiest method to identify rebar. Let me tell you more about using on-demand color rebar tags.

Brooklyn Rebar (http://www.brooklynrebar.com/) is a rebar fabrication company committed to serving contractors and warehouses in New York, Connecticut and New Jersey. They provide fabricated rebar to complex, large and small bridges, concrete high rises, tunnels, treatment plants, power plants, ranging in size, from 1 to 10,000 tons of rebar. Brooklyn Rebar is located on the Brooklyn/Queens line with easy access to all east side tunnels and bridges into Manhattan.

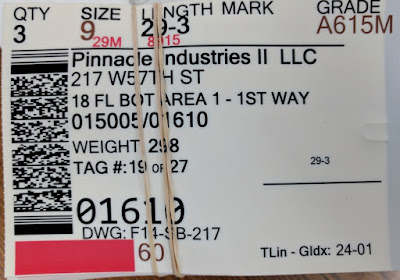

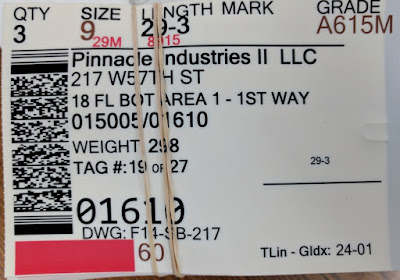

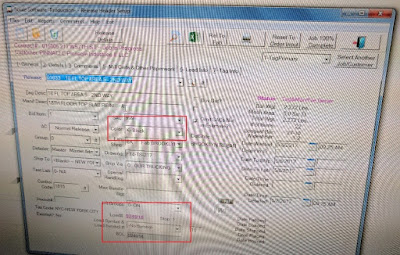

In January 2016, a Project Manager, of Brooklyn Rebar contacted us to discuss how they could print color tags for their rebar. During our conversation and subsequent work together, I learned that Brooklyn Rebar uses Soule Software, (http://www.soulesoftware.com/), which offers a complete suite of software for rebar fabricators and placers. In their software, Soule built the capability to use color in their customer’s operations. According to Bob Boeving, Vice President of Sales for Soule Software, “Color has become a very valuable tool for rebar fabricators. Now fabricators can add color bars to their tags to help the job site stage and locate the correct materials for each specific part of a project. Fabricators can set up unique colors for each section of a project, which print automatically. This color capability helps contractors reduce errors and increase productivity on the job site.”

Bob continues, “color on-demand tags helps fabricators as well to stage, load and offload rebar correctly. With color, fabricators can pull off the truck rebar in the correct sequence. In addition, our software enables the use of images to show unique dimensions or bends in the rebar. These images help the fab shop understand what’s required to reduce potential errors. We can also use color to identify foreign or domestic steel; and to identify different grades of steel. This color identification helps the fab shop pull the correct steel inventory for their job. Overall, color on-demand tags are a powerful tool to help reduce errors in a rebar operation.”

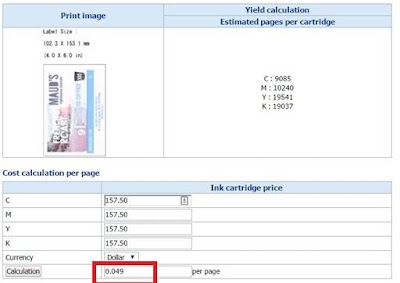

Based on the capability of the Soule Software, Brooklyn Rebar purchased a C7500 and 4” x 6” matte poly tags.

|

| Print On-Demand Color Rebar Tag |

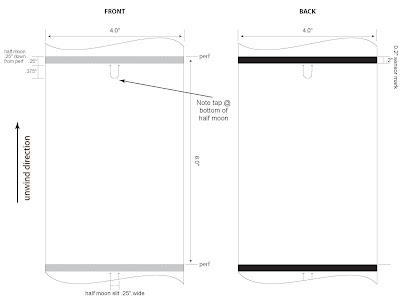

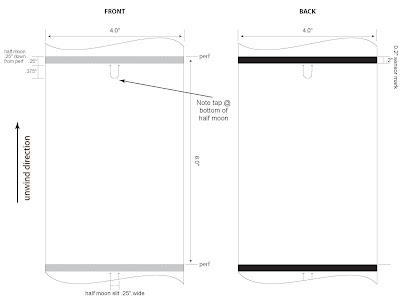

Initially, we had issues with the tags. First, we learned the C7500 can’t use standard shaped tags; tags with a notch for thermal transfer printers to detect top of form. When the printer pulls the tags back into the printer to start printing, the notches catch causing the printer to error out. Second, we tried new material with a shinier back. Although the tags would work in a C3500, they would not function in a C7500. It seems the C7500 has a substantially different blackmark sensor. The reflection on the back of the tag caused the printer to misread the blackmark. Third, we tried a thinner, 5 mil poly tag. Although durable, the 5 mil tag could tear at the notch, potentially losing the tags during shipping or moving in the yard. Because of these problems, we had supply issues, getting the tags to our customer. One aspect of the 5 mil tag; they print great!

|

| 5 Mil On-Demand Color Tag |

Through all these start up issues, Brooklyn Rebar stayed with us. And we appreciated their support. Ultimately, we settled on an 8 mil, matte poly tag with the design in the image above. And these thicker 8 mil tags seem to be working well.

|

| Print On-Demand Color Rebar Tag |

During a recent visit, a Project Manager for Brooklyn Rebar, showed me how they use color in their operation. According to the Project Manager, “we assign colors to specific areas of the project, using the Soule Software.”

|

| Color Rebar Staging Document |

“And in the software, it’s easy to pick the color for each section of the project”, said the Project Manager.

|

| Soule Software Color Selection |

“We use both solid colors and different color hash marks for each of the locations on a project. For most projects, the solid colors are sufficient. When we need more locations, we use different color hash marks. We find the color coding helps our customers and us internally to reduce errors and increase our productivity”, said the Project Manager.

After working with Brooklyn Rebar and learning more about Soule Software, I do believe automating color codes on tags will help fabricators significantly. Plus I like the fact that Soule built in the capability in advance of available technology; specifically the C7500. Even today, I know of software applications that have been built using printing languages from the 1980’s.

And more importantly, I appreciate companies like Brooklyn Rebar who search and use practical technology that improves their productivity and reduces the potential for errors.

If you need a color-coded label or tag solution for rebar or any other item, be sure to contact us. We would enjoy working with you to build a color-based solution that fits your business.

Guy Mikel

855-962-7670