We supply “get-it-right first time” induction sealing equipment that represents a best value proposition for your needs. For less demanding tasks the CE certified SealerOn™ For more demanding tasks we have teamed up with MeRo Italy; European OEM.

Category: Induction and Heat Sealing Machines

SealerOn™ Induction Sealing Machines

We believe there is no better value Basic Induction Sealing Equipment on the market today.

The SealerOn™ Basic Induction Machine range is offered to achieve Optimal:

- Machine Value

- Entry Level Induction Sealing

- Reliability

- European Compliance (safe) Equipment

SealerOn™ Basic Induction Sealing Machine Features incorporated into this range include:

- Air Cooled

- Simple Controls

- Semi-Automatic Induction Sealing Option

- Capless Semi-Automatic Induction Sealing Option

- Mid Level Automatic Induction Sealing Option

- Emergency Stop on Mid Level Unit

MeRo Induction Sealing Machines

We believe there is no better value medium priced “High End” Induction Sealing Equipment. There are unique features to allow process validation and adjustable width sealing head tunnels are available.

MeRo Induction Systems feature:

MeRo Induction Systems feature:

- An Air cooled system (Absolutely no need to water cool the induction head).

- Compact construction for easy integration into the filling line.

- High power efficiency thanks to the configuration of the power circuits and the use of IGBT modules.

- Sinusoidal output waveform (Not Square or chopped).

- Constant and Precise Output power due to the configuration of the regulation circuits.

- Easy to use controls that display operating parameters and alarm signals.

- Remote control Start-Stop interface.

- Power variation monitor which can be set by the user to activate an alarm.

- Manufactured in accordance with EN-60204-1 standards, Electromagnetic (EMC) compatibility in accordance with EN-5511 and EN50082-2 standards.

- Motorized height adjustment

- Set-Up Validation providing an Energy absorbed reading- A key advantage over Nearly Every other make

Depending on the range of product and cap/lid/closure shapes, different sealing heads can be supplied.

Options include:

- Missing Foil Detection with Bottle Eject Mechanism or Signal

- Bottle Accumulation Detection to avoid the situation where bottles are stalled under the active sealing head.

- Pressurized Cabinet version to work in dangerous areas.

- Fieldbus connection to the production process ASI/PROFIBUS/CAM OPEN/DEVICE NET

- Integration of power regulation proportional to the speed of the conveyor via feedback from your existing conveyor’s speed controller. This is another key advantage that MeRo are able to offer over nearly other make.

Induction Sealing

Heat Sealing Versus Induction Sealing

What is the difference between a heat sealing machine and an induction sealing machine? This paper examines the difference in the case of an automated line.

Often, clients new to packaging approach Benefel asking for heat sealing equipment to seal their product without realising that this older, less sophisticated method of sealing a product is not what they really want. In terms of machine versatility, pricing, safety and set up nearly all these clients are better served using induction seal machinery.

Below are some key differences in the sealing machinery and sealing process:

Heat sealing machinery disadvantages:

- Products are sealed without their cap or lid in place.

- Product handling is more complicated when automated as the products need to be transported, without spillage, in the sealing machine using cups or turrets in open containers.

- Machinery is more dedicated to specific sizes of containers, given the complexity of transporting open containers.

- Versatility of heat sealing machinery is limited and requires significant change parts if a different size or shape container is to be sealed using the same machine.

- There is a physical source of heat that comes into contact with the container to melt the seal in place.

- The machinery is often rotary in nature increasing the size and cost of equipment compared to induction sealing machinery.

- The process cannot be started instantly as the physical sealing heat required needs the sealing element(s) to reach temperature.

- Physical handling of the product means the machine has many more service and set up issues compared to the induction sealing process where there is no physical contact.

- Heat sealing requires a larger sealing surface to work well; for instance if you look at a Yoghurt tub you will see the packaging is designed with a turned out flat rim to accept the heat sealing foil.

Heat sealing machine advantages:

- The sealing material per unit is usually less than induction sealing material.

- Products can be sealed without a lid or cap. Note there are Capless induction sealing machines but they are not so common and are usually more expensive.

- You can visually inspect each seal as there is no cap or lid covering the seal during the sealing process.

- Very low cost plastic seals (without a metal foil layer) can be used. This is a big advantage when the primary reasons for sealing do not include moisture and oxygen barrier requirements.

- Larger diameter jobs beyond 70mm will use a large amount of sealing material per item and hence the availability of lower cost sealing films becomes a more significant advantage for heat sealing.

To list the induction machine advantages and disadvantages would be to simply reverse the above mentioned factors. Nevertheless the benefits of induction sealing can be summarised below:

- Induction machines have a smaller machine foot print

- Induction machines are lower priced

- Induction machines do not need to touch or handle the product

- Induction machines are simpler and safer to operate having no physical source of heat

- Induction machines are versatile and can handle many different shapes and sizes of containers.

- Induction machines can be powered on and ready for production nearly instantly.

- Induction machines are much faster to adjust and set up for different jobs.

- Induction machines are far easier to move from one production line to another as they can simply be wheeled into place over an existing section of conveyor.

There are companies that are dedicated to converting old heat sealing machines over to induction sealing machines, whereas the reverse case does not exist pointing to the generally accepted opinion that when you need to seal a Jar or bottle the most likely method will be with an induction seal.

There is still a place for heat sealing usually limited to applications where the sealing diameter is more than 70mm and the volumes of the same size product are very large and changeover of sizes and shapes is not required. The other main application for heat sealing will be where the product has no lid or cover and the sealing film is what is relied upon to complete the package.

Packaging in Glass or PET When Considering Induction Seal

Often there are clients packaging a “pure” product which they are packaging in Glass.

The problem they face is that they are having leaking issues and also want some tamper evidence or freshness seal. In the case of dry products like capsules or powders there are some good options. Take for example coffee which is often packed in glass and has a foil freshness heat seal across the opening of the Jar.

In the case of wet and oily products the Induction Sealing option is not available. The heat sealing process in induction sealing relies on a layer of material laminated to the foil becoming “wet” when it is heated and then setting or drying when the foil cools down. In the case of plastics bottles this sealing layer is usually a plastic based sealing layer that “melts” into the existing plastic of the container. For glass with very high melt temperatures the sealing layer never gets anywhere near hot enough to “melt” into the glass so this sealing layer is usually adhesive based. Wet products and oily products tend to seep into this seal after the sealing process, eventually weakening or neutralising the adhesive and breaking the seal.

Another hurdle to get past with glass jars is that more often than not they are designed or supplied with metal caps. The induction sealing process relies on an uninterrupted magnetic field to work on the foil layer of an induction seal to heat that seal. Metal caps or closures interrupt the seal and the metal cap tends to absorb the heat sealing energy before the induction material receives this energy.

While often it is environmental or health based products packed into glass, ironically these manufactures are making a much larger impact on the environment in using glass packaging than their counterparts using PET packaging.

While often it is environmental or health based products packed into glass, ironically these manufactures are making a much larger impact on the environment in using glass packaging than their counterparts using PET packaging.

We will not enter into the argument about whether Glass or Plastic is best to package products but rather we will focus on the limitations lifted on induction sealing when using plastic packaging with plastic lids.

There are many products that transition from glass to plastic and are using plastic packs that look like glass yet still have metal lids. These products can be induction sealed using Capless induction sealing. This is a process where the open filled product passed under a sealing head that first cuts a disc of sealing foil, locates that sealing foil over the products opening and then heat seals that foil to the container. After this sealing machine process the package has its metal cap put in place.

More recently plastic packs that look like glass packs are now having screw on sections enabling the development and application of plastic caps. It is the combination of a plastic bottle and a plastic cap that best lend themselves to the induction sealing machine process.

For the pure products market that simply must have their product in glass ,not all hope is lost for induction sealing as development of adhesives for the induction sealing layer that are suitable for glass and resistant to wet and oily products is still taking place. There are definitely some glass sealing foils that perform better than others and the best way to know if your product will suit will be via trials. The longer you can conduct your trials and the more varied conditions, such as temperature ranges and pressure ranges the more certain you can be that the induction sealing process is suited to your application.

What Shape Sealing Head is Best on an Induction Sealers?

Induction Sealers

To understand this question of the sealing head shape we must first understand how an induction seal is achieved.

The sealing head is the part of the machine that is placed over the path of the product cap/lid. Within the sealing head is usually long oval shaped coils of thick wire that carry high current that changes direction many thousands of times a second. This creates a magnetic field at right angles to the coil that also changes direction many thousands of times a second. The magnetic field can travel through air and plastic but it does get weaker as it travels away from the coils that generated the magnetic field. When the magnetic field comes across metal, it will act to generate current in the metal.

In the case of the heat sealing machine, it waits for a product that has a metal laminated foil in its cap. The magnetic field from the sealing head acts to generate current in the laminated foil and the laminated foil gets hot. Laminated to the foil is a layer that will melt or become “wet” with heat. When the product has completely passed from under the induction machine the foil will begin to cool and the layer that became “wet” will set to bond the laminated foil across the opening of the product.

From the above “theory” it can be understood that the sealing of a bottle or product using induction machines will depend on how long the product is under the magnetic field and how close it gets to that origins of the magnetic field.

There are two distinct shapes of sealing heads for cap sealers being Flat profile and Tunnel profile sealing heads.

The Flat profile sealing head is suitable for “Standard Flat Caps” . A “Flat Cap”, generally speaking, refers to a cap where the plane of the induction liner is within 4.0 mm of the plane of the Cap’s top surface.

The Tunnel profile sealing head is suitable for “Specialty Caps”. A Tunnel Induction Sealing Head lets you seal caps where the foil sits a distance greater than say 4 mm from the top surface of the cap; this is often the case with twist top spouts, flip top lids, sports drink caps, sipper caps or shaker caps.

The Tunnel sealing head concentrates the magnetic field to an area within the tunnel profile and hence provides stronger magnetic fields over a generally smaller width path for the products passing underneath. A Tunnel sealing head also allows the coils within the sealing head to have a path lower than the top of the product caps. This brings the magnetic field closer to the plane of the foil within “specialty caps”. The drawback to this Tunnel profile sealing head is that it is usually not very good for large caps and it does limit the range of cap sizes that can be efficiently sealed. There is a small exception to this rule with the MeRo™ brand induction sealer with an adjustable width tunnel profile. This machine can typically cater for a range of specialty caps with an adjustment of 30mm which would mean a typical cap diameter range of 30mm to 60mm could be very efficiently sealed.

Efficient cap sealing means that less time is needed under the sealing head and hence higher production speed is possible.

A Flat profile sealing head will allow for a greater range of cap sizes and even allows for that Sealing head to be placed at an angle across the product’s path to achieve sealing of cap diameters that are even wider than the coil winding pattern within the sealing head. It is quite possible to have a Flat profile sealing head that can seal caps from 30mm to 110mm wide. The trade-off for the versatility of this profile sealing head on a heat sealing head is lower speed throughput and an inability to seal specialty caps.

Line Patrolman™ Unique Process Validation Tool for Induction Sealing

As a result of many unknown variables which may significantly impact sealing results of an induction machine, an induction sealing process validation is highly advised.

The sealing machine could be bumped on a small angle, a slight height adjustment might have been made, large bottle height variations, and conveyor speed variations can all drastically impact the induction sealing results.

Visual Inspections Process Validation for Induction Sealing

For properly trained operators, this process can be the best of all; in particular when they are competent exactly how induction foils look like when they have obtained the precise conditions for a good seal.

Some things to look for include:

a) A Concentric heat pattern in the foil; when you hold the foil to some light source with the accurate position you should observe a smaller sized circle where material was not heat affected. This implies the seal has heated externally then inwards in an even pattern; therefore a good seal.

b) Overheating – there are numerous of aspects to point out if there have been overheating including visual discolouration of one or more layers of the induction foil, bubbling or creasing, a flattening of the bottle neck, melting of a backing resealing foam (if there are any).

c) Unequal heat sealing; associated in some ways to (a) above; a foil can look nicely sealed but an unequal heat seal can result in aspects of the seal being too tightly “welded” or very lightly welded and more likely to “pop loose with some pressure on the side walls of the bottle/container.

So long as you have operators in each shift that happen to be properly trained in the above areas to consider, then the “subjectivity” of a visual process validation is reduced and the validation will hold more benefit.

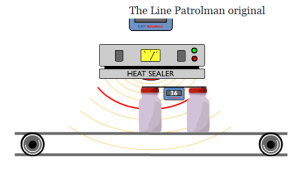

2.0 Basic version – Linepatrolman™ Process Validation for Induction Sealing

Should you have doubts that you’re going to always have operators properly trained or experienced enough to cover what exactly is required for a

reliable visual process of validation for induction sealing then there is the straightforward option of a Linepatrolman™ which has no additional controls than a reset button.

This unit needs absolutely no programming and simply provides an built-in count of the energy seen by the testing cell moving about the same path as the products.

The Benefel site has a good animation of the Linepatrolman™

In this animation, the count gets up to “50”. If that reading worked for the last batch and was verified being a good reading by a very comprehensive visual assessment (as well as some leak screening), operators would look to obtain equivalent readings in next production runs of the same product.

Many organisations need an induction sealing measurement since the whole process is a time and position dependent. When there is speed variance as the product passes through the induction machine the outcome is likewise different. For an operator a 10% alteration of the speed of a product conveyor may not be found. To an operator a 1mm height adjustment of the sealing head most likely is not noticed or a 5 degree angle difference in guide rails could possibly be missed. The induction sealing setting on the induction sealing machine may not have changed at all, but the sealing effects would have changed considerably!

The Line Patrolman™ is a unique process validation device that can pick up changes in energy transfer in what may seem like an identical set-up to the last time an induction machine has been operated. This eliminates guess work on the energy transfer and give confidence that the machine is set to the ideal settings.

Induction Sealing Bottles with Specialty Caps

Induction Sealing

A Tunnel Induction Sealing Head lets you seal caps where the foil sits a distance greater than say 4 mm from the top surface of the cap; This is often the case with twist top spouts, flip top lids, sports drink caps, sipper caps or shaker caps.

Induction sealing is a process where a coil in the shape of an elongated loop is used to generate a fast oscillating high magnetic field. This magnetic field can change poles as many as 100,000 times every second.

The magnetic field can travel through air and plastic. When the magnetic field meets a metal surface, the magnetic field “induces” a high oscillating current in that metal surface in a plane that is parallel to the coils that generated the magnetic field.

A magnetic field generated from a “point” dissipates with the cube of its distance from that point.

In general, the magnetic field of an induction sealing machine needs to be within 5mm or ¼ inch from the sealing foil to obtain meaningful production speeds.

There are a large range of caps that do not fit the standard flat top profile and present a problem to bring the magnetic field of the heat sealing equipment to within 5mm or ¼ inch from the sealing foil.

These specialty caps need an adaption from a standard flat coil sealing head to a tunnel sealing head. The Coils are shaped to pass around the tunnel. The tunnel allows the protruding feature of the specialty caps to pass through the machine without lifting the plane of the magnetic field further away from the sealing foil within the bottle cap.

On the SealerOn website there is a youtube icon that will link you to videos showing SealerOn™ heat sealing or more accurately induction heat sealing using a tunnel sealing head.

The SealerOn™500 fitted with a sealing tunnel is capable of sealing at sealing speed up to 10 Meters per Minutes or 30 Feet per Minute depending on the cap and foil combination.

For faster induction sealing there is the MeRo adjustable tunnel sealing machines. These machines have the added and unique feature of having an adjustable width sealing head. Having an adjustable width enables higher concentrating and focussing of the induction field allowing for higher speed sealing. A MeRo 2Kw unit is capable of sealing at sealing speed up to 30 Meters per Minutes or 90 Feet per Minute depending on the cap and foil combination.

Efficient cap sealing means that less time is needed under the sealing head and hence higher production speed is possible.

A Flat profile sealing head will allow for a greater range of cap sizes and even allows for that Sealing head to be placed at an angle across the product’s path to achieve sealing of cap diameters that are even wider than the coil winding pattern within the sealing head. It is quite possible to have a Flat profile sealing head that can seal caps from 30mm to 110mm wide. The trade-off for the versatility of this profile sealing head on a heat sealing head is lower speed throughput and an inability to seal specialty caps.

Safe, Affordable, Handheld or Bench Top Induction Sealing Machine

Following frequent inquiries from smaller businesses, some start up companies, and testing labs looking for a reasonably priced induction machine, we have decided to make available a safe and affordable induction sealing unit.

Smaller businesses have low budgets in mind, but it doesn’t mean that they are ready to compromise machine safety and the integrity of their products. Regrettably, there are not too many good options available in the market. The majority of low cost induction sealing units do not present CE safety certification for LV and EMF.

Induction Machine CE Safety Certification for LV and EMF

The CE mark should be applied in order to legitimately market electrical and electronic products in the European Union (EU), but only after you have proven compliance with all applicable directives. Compliance is established by testing the applicable harmonized standards for the safety of electrical and electronic products in relation to the effects of electromagnetic fields (EMF) and EMC on the functional safety of equipment. CE marking requirements now include compliance with electromagnetic field and electromagnetic compatibility standards. Manufacturers must ensure that products already on the market comply. This is precisely the reason why almost all other low cost induction sealing units do not have this CE safety certification.

Safe Induction Machine Option

The conception of SealerOn100™ was brought about by this need to supply the market with a machine that is certified safe and efficient. Induction machines generate high current and high electromagnetic field to accomplish their tasks. The birth of SealerOn™-100 has filled a gap in the SealerOn™ range that has provided a dependable solution to higher throughput equipment our clients are familiar with and put their trust in.

Immediately after its initial launch, we were flooded by a large number of inquiries. The unit is fully serviceable and it is fashioned to have its main electronics replaced in under 5 minutes! Watch our video:

How Induction Sealing Takes Place

Induction sealing is a straightforward and simple process but an efficient way to seal bottles. The filling machines fill the bottles and are capped at some point. The plastic cap has an aluminium foil liner inside. Once the capped bottle passes under the induction sealing machine, which transmits electromagnetic energy to the foil liner, the liner becomes hot and welds itself to the neck of the container which remains in place even when the cap is removed. The aluminium foil provides a tight seal that helps prevent leakage, provides tamper evidence and can improve the shelf life of the product.

For small production run of sealing a few hundred units a day, SealerOn™-100 is a good solution. Highly recommended for:

- smaller or start-ups businesses looking to introduce a new product in the market

- ideal for laboratory testing and applications

- a low cost backup measure for higher end induction equipment

When you have time to properly align the sealing head visually, the SealerOn™-100 can be supplied with just a sealing head or wand. To insure a steady and even sealing, it is essential that the sealing head is level and well centered. The option of a stand to hold the sealing head and a locating bracket that aligns the product under the sealing head is made available to eliminate alignment errors.

We are proud of our SealerOn™ range of induction sealing equipment that performs reliably, safely and are easily serviced. We are delighted to be able to present a realistic and safe alternative for those in need of low budget, bench top or hand held induction sealing machine.